Integrated Management of Corporate Environmental Information

In order to implement the PDCA cycle for environmental sustainability management, it is essential to collect a significant amount of data, such as amounts of used energy, waste, valuables, discharged and transferred chemical substances, and used water, etc. at each business site in a prompt and accurate manner.

Panasonic Group has built and introduced an environmental performance system, the Eco System (Factory), to globally collect and manage environmental data from all of own business sites. With this system, monthly CO2 emissions are managed in particular, allowing checking the progress of initiatives and identifying issues. The system plays an important role in achieving the reduction of CO2 emissions by sharing the information and taking measures.

The Eco System (Factory) is also functioning as a scheme for sharing information on the status of compliance among sites across the world. In the event of complaints from local community residents or when a specific value exceeds ordinance regulated levels, as soon as the person in charge at the business site inputs the data on the system, information of the data is instantaneously e-mailed to relevant persons at the operating companies and the Quality & Environment Division of Panasonic Operational Excellence Co., Ltd. Thereby, the system enables rapid informationsharing and appropriate actions.

Mechanism of the Eco System (Factory)

In addition, Panasonic Group newly established an environmental information infrastructure, aiming to store and share the data necessary for promotion of Panasonic GREEN IMPACT, and for disclosure and appeal of the environmental data, in order to respond to legal demands appropriately and efficiently for environmental information disclosure and stakeholders' requests. The infrastructure centrally manages the information related to calculation and tally of CO2 emissions across the entire value chain (Scopes 1, 2, and 3), as well as information on the avoided emissions.

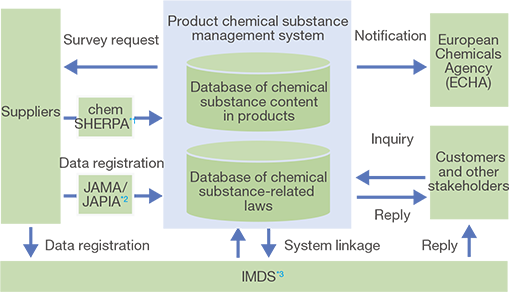

As for products, legislation relating to chemical substances in products is becoming more stringent in the world, for example, and communication and disclosure of chemical information in the EU supply chain are mandatory under the REACH Regulations. The Panasonic Group has developed own management system for chemical substances in products based on industry-standard information handling methods in order to respond to a wide range of regulations and requirements.

In January 2017, we renewed our product chemical substance management system to adopt chemSHERPA*1 based on EC62474, the international standard on material declaration for electrical and electronic equipment, i.e., declaration of information of chemical substances and materials comprise such products. Along with the expansion of Panasonic Group's automotive business, we also adopted the JAMA/JAPIA integrated data sheet,*2 the standard material data format for the Japanese automotive industry.

These adoptions enabled us to respond to increasingly complex and diverse regulations covering the chemical substances used in products in a variety of fields. In addition, to strengthen the response to laws and regulations on chemical substances in products relevant to our automotive businesses, in October 2020 we enhanced the function to operate in conjunction with IMDS,*3 the standard system for the global automobile industry.

Furthermore, under the EU Waste Framework Directive, the requirements for information disclosure on substances of very high concern (SVHC*4) to waste disposal companies and consumers have been enhanced, and registration of SVHCs with the SCIP*5 database of the European Chemicals Agency (ECHA) has become compulsory (starting on January 5, 2021). For handling registration with the SCIP database, we have strengthened the system-based coordination of information and started registration via the Panasonic Group system.

Mechanism of the Product chemical substance management system

*1 New chemical information format led by METI and recommended by the Joint Article Management Promotion-Consortium (JAMP).

*2 A standardized survey datasheet for contained chemical compounds in Japan's automotive industry. The JAPIA Standard Material Datasheet prepared and introduced by the Japan Auto Parts Industries Association (JAPIA) is currently used as its successor tool.

*3 International Material Data System: Material data system for the automobile industry that are operated on a global scale.

*4 Substances of Very High Concern

*5 Substances of Concern In articles as such or in complex objects (Products)