- Automaic Copy Shaper

- Beam Saw

- CNC Routers

- Cold Press

- Dust Controllers

- Edge Banders

- Four Side Moulders

- Glu Spreader

- Highspeed Routers

- Hot Press

- Multi Boring

- Ocsillation Mortiser

- Panel Saw

- Postform

- Spindle Molder

- Tenoners

- Trimmers

- Vacuum Mambrane Press

Automaic Copy Shaper

Continuous multi-station working. High production capacity ...

Machine available in various sizes & configurations, with cutting diameter from 10" to 72" and with single cutter head & double cutter head.

Precision & Flexibility with advanced design capabilities to meet the most demanding craftsmen!

Technical specifications available on request

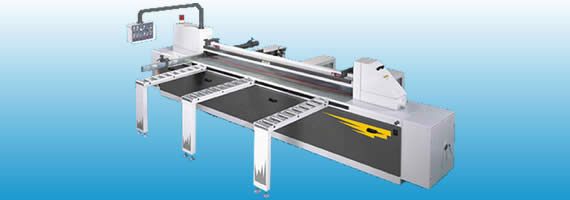

Beam Saw

Model: Beam Saw J-320 MB

Higher production out-put with excellent cutting of multiple panels, made easy and cost effective.

Advanced Saw Carriage : The saw carriage feed is driven by rugged wire. Fitted with a shock absorbing cylinder to prevent bumping while it travels to the left side. The scoring blade may be laterally adjusted for a burr free cut or vertically adjusted for proper depth of cut and to compensate for blade wear.

Scoring Sawblade Adjustment : The scoring sawblade can be adjusted vertically for depth of cut control. Once wear occured, adjust its position for compensation. The scoring sawblade also can be adjusted laterally for alignment to main sawblade.

Precise Saw Stroke Control by Optical Fiber Sensor : The machine employs an advanced, high performance, optical fiber sensor. Its highly sensitive performance ensures extremely accurate saw stroke control.

Features :

1 - Advanced saw carriage with high feed rate driven by rugged wire and guided on hard guide rods that ensures high cutting accuracy.

2 - Precision saw stroke control by sensor.

3 - A uniform holding pneumatic clamping beam ensuring synchronized cylinder actuation at both ends.

4 - Adequate safety systems to avoid accidents due to unwanted travel of saw carriage.

5 - Piano type dust guard which prevents saw dust for being sprayed out during cutting operation of machine.

6 - Warning lamp to indicate over load on motors during cutting operation.

7 - Easy accessible PLC system control panel

| Sr.No | Unit | J-320 MB (manual) | |

|---|---|---|---|

| Capacity | |||

| 1 | Maximum length of cut | mm | 3250 |

| 2 | Maximum depth of cut | mm | 80 |

| Main Saw Unit | |||

| 3 | Maximum blade diameter | mm | 355 |

| 4 | Arbor diameter | mm | 40 |

| 5 | RPM of main saw blade | rpm | 4800 |

| Scoring Saw Unit | |||

| 6 | Maximum blade diameter | mm | 160 |

| 7 | Arbor diameter | mm | 25.4 |

| 8 | RPM of scoring saw blade | rpm | 6500 |

| Saw Carriage | |||

| 9 | Feed forward speed | m/min | 12 / 16 / 21 / 26 |

| 10 | Retract speed | m/min | 24 / 32 / 42 / 52 |

| Motors | |||

| 11 | Main saw unit, motor | hp | 13 |

| 12 | Scoring saw motor | hp | included in above |

| 13 | Saw carriage, motor | hp | 3 |

| Other Specifications | |||

| 14 | Table height from floor | mm | 820 |

| 15 | Working air pressure | kg/cm2 | 5 to 6 |

| 16 | Dust extraction port diameter | mm | 100 |

| 17 | Machine dimensions (LxBxH) | mm | 5842x3353x1829 |

| 18 | Approx net weight | kg | 2400 |

CNC Routers

Models: CNC Routers J-1218 | J-1224 | J-1325 | J-1535 | J-2030

Make your industry High-tech, at an affordable cost

Precision Vacuum Table (optional) : For vacuumed fixing and sure clamping of the workpiece, to ensure steadiness during the entire routing operations. Digital signal processing for Control System.

Features :

Taiwan linear rail with high precision

German ball screw with high accuracy

Cast steel structure makes our routers more stable

Auto lubrication makes maintenance much easier.

| Sr.# | Unit | J-1218 | J-1224 | |

|---|---|---|---|---|

| 1 | X-Y-Z axis working area | mm | 1200 x 1800 x 120 | 1220 x 2440 x 120 |

| 2 | Resolutions | mm | 0.025 | 0.025 |

| 3 | X-Y movement | Rack & pinion, gear drive/Taiwan | Rack & pinion, gear drive/Taiwan | |

| 4 | Z Movement | Ball screw drive Germany | Ball screw drive Germany | |

| 5 | Maximum speed | mm/min | 35000 | 35000 |

| 6 | Maximum cutting speed | mm/min | 25000 | 25000 |

| 7 | Spindle | 4 Hp, Water cooling, 24000rpm | 4 Hp, Water cooling, 24000rpm | |

| 8 | Drive motors | Stepper | Stepper | |

| 9 | Working voltage | AC 380V / 50Hz,3Ø | AC 380V / 50Hz,3Ø | |

| 10 | Command code | G code | G code | |

| 11 | Computer | USB 2.0 | USB 2.0 | |

| 12 | Collet type & size | mm | ER20 (12.7,6,3.175) | ER20 (12.7,6,3.175) |

| 13 | Software | Type-3 | Type-3 | |

| 14 | Controls | Digital signal processor | Digital signal processor | |

| 15 | Oil lubrication system | Standard | Standard | |

| 16 | Vacuum table | Optional | Optional | |

| 17 | Machine size | mm | 1750 x 2760 | 1750 x 2760 |

| 18 | Packing dimensions | mm | 2560 x 1860 x 1720 | 3160 x 1860 x 1720 |

| 19 | Approx. weight | kg | 900 | 1050 |

Cold Press

Models: Cold Press J-50 T | J-80 T

Panel board strength & durability, as never seen before!

Compression holding timer, Pressure settings with indicator. Rigid construction, platen designed to take heavy compression loads.

Application :

Machine suitable for pressing various types of laminations on composite wood, cork board, fiber board. Honeycomb board.

Having various applications for furniture & boards lamination Industries.

Features :

Manual & semi-automatic controls.

Emergency stop switches.

Motor overload relay.

| Sr.No | Unit | J-50 T | J-80 T | |

|---|---|---|---|---|

| 1 | Maximum load on work table | Ton | 50 | 80 |

| 2 | Platen size | mm | 2500 x 1250 | 2500 x 1300 |

| 3 | Maximum platen opening | mm | 1000 | 1300 |

| 4 | Number of hydraulic cylinder | No. | 2 | 2 |

| 5 | Size of hydraulic cylinder | mm | 125 Ø | 160 Ø |

| 6 | Installed power | kw | 4 | 5.5 |

| 7 | Machine dimension (LxBxH) | mm | 3000 x 1250 x 3050 | 3150 x 1300 x 3500 |

| 8 | Approx.net weight | kg | 2850 | 3500 |

Dust Controllers

Models:

Dust Controller DC-31 | DC-42 | DC-21 | DC-32 | DC-52 | DC-74 | DC-104

It makes your Men & Machine work better and longer by keeping them healthy!

Application :

Dust Collectors are used along with wood working and other machineries as a catcher of saw dust, chips, shavings & granular materials from the operating area. The unit is fitted with dynamically balanced steel impellers, which is housed in a profiled housing to give high volume and efficient suction capacity. Thus preventing saw dust entering into working parts of the machines; hence protecting the moving parts from premature wear & tear and also giving clean working conditions.

The dust is sucked in the pump and is collected in a filter bag having about 30 micron rating which is supplied as a standard accessory. The drive is through a 3-Ø induction motor. The base frame is mounted on swivel wheels for easy portability of the unit. Various sizes of the dust collectors are available depending upon the number of machines and amount of saw dust to be evacuated.

Features :

Statically balanced high speed impellers gives vibration free efficient spindles

Available in different size, depending on suction capacity

Available in 1 bag, 2 bags & 4 bags configuration

Mounted on base frame with wheels for easy portability

| Sr.# | One Bag Models | Unit | DC-21 | DC-31 |

|---|---|---|---|---|

| 1 | Material of bag | - | Fabric filter | Fabric filter |

| 2 | Micron rating of bag | - | 30 | 30 |

| 3 | No. of bags for air venting | nos. | 1 | 1 |

| 4 | No. of bags for dust collection | nos. | 1 | 1 |

| 5 | Air suction capacity | m³/hour | 2000 | 2500 |

| 6 | Max. static pressure | mm H²O | 250 | 300 |

| 7 | Intake opening | dia. | 100mm x 2 | 100mm x 2 |

| 8 | Motor - 3 Ø | hp | 2 | 3 |

| 9 | Approx. net weight | kg. | 60 | 52 |

| Sr.# | Two Bag Models | Unit | DC-32 | DC-42 | DC-52 |

|---|---|---|---|---|---|

| 1 | Material of bag | - | Fabric filter | Fabric filter | Fabric filter |

| 2 | Micron rating of bag | - | 30 | 30 | 30 |

| 3 | No. of bags for air venting | nos. | 2 | 2 | 2 |

| 4 | No. of bags for dust collection | nos. | 2 | 2 | 2 |

| 5 | Air suction capacity | m³/hour | 3000 | 4000 | 5000 |

| 6 | Max. static pressure | mm H²O | 400 | 450 | 475 |

| 7 | Intake opening | dia. | 100mm x 3 | 100mm x 3 | 100mm x 3 |

| 8 | Motor - 3 Ø | hp | 3 | 4 | 5 |

| 9 | Approx. net weight | kg. | 92 | 65 | 105 |

| Sr.# | Four Bag Models | Unit | DC-74 | DC-104 |

|---|---|---|---|---|

| 1 | Material of bag | - | Fabric filter | Fabric filter |

| 2 | Micron rating of bag | - | 30 | 30 |

| 3 | No. of bags for air venting | nos. | 4 | 4 |

| 4 | No. of bags for dust collection | nos. | 4 | 4 |

| 5 | Air suction capacity | m³/hour | 7500 | 11000 |

| 6 | Max. static pressure | mm H²O | 500 | 550 |

| 7 | Intake opening | dia. | 100mm x 5 | 100mm x 5 |

| 8 | Motor - 3 Ø | hp | 7.5 | 10 |

| 9 | Approx. net weight | kg. | 171 | 184 |

Edge Banders

Models:

Curvilinear Edge Bander J-3000.in

Semi Auto Edge Banders J-4003 / 4004

Auto Edge Bander J-5000.in

Automizing crucial functions to increase precision and production

Curvilinear Edge Bander : This is an extremely flexible machine for application of PVC/ABS or Veneer on straight or shaped panels. The thickness of banding material can be from 0.5mm to 3mm and the machine is designed to accomodate a panel of 10-60 mm in thickness. The Edge Banding is a semi-automatic machine, wherein the predefined length of PVC/ABS to be glued to the laminate can be set for repetitive workpiece and the digital temp. controler and the speed regulator maintains the gluing temperature and feed rate of tap respectively to have an effective banding of PVC/ABS to the workpiece.

The machine has a specially designed hylum surface working table for heat insulation and side roller support at both ends, which helps in easy movement and feeding of workpiece on the table. The machine guarantees perfect glueing at all times and is versatile and suitable to be used by small and large manufacturers.

Semi Auto Edge Banders : With auto feeding & gluing of banding coil of up to 3 mm. A versatile m/c, it can handle melamine, veneer & PVC coils. Very user friendly controls

Auto Edge Banders : J-5000.in from 'Pride of India' range, is the most succesfull india made Euro-quality m/c. Most comprehensive workability and proven performance records. Best buy today.

| Sr.# | Unit | J-5000.in (auto) | |

|---|---|---|---|

| 1 | Work piece thickness range | mm | 8 - 60 |

| 2 | Min. work piece width / length | mm | 80 / 140 |

| 3 | Edge banding thickness for PVC & ABS in coil form | mm | 0.4 - 3 |

| 4 | Thickness of wooden strips | mm | up to 10 |

| 5 | Dual feed speed - For PVC Coil - For Wooden Strip |

m/min. m/min. |

11 6 |

| 6 | Glue Pot Unit - absorbed power - glue granules capacity - working temperature |

hp Kg º C |

1.5 1.5 180 - 200º |

| 7 | End cutting unit - motor power - speed of cutters - blades tilting |

nos/ hp rpm deg |

2 x 1 12000 0-15º |

| 8 | Edge Trimming Unit - motor power - speed of cutters |

nos/ hp rpm |

2 x 1 12000 |

| 9 | Buffing unit - motor power - speed of wheel |

nos/ hp rpm |

2 x 0.5 1400 |

| 10 | Air Pressure | Kg /cm² | 5 - 7 |

| 11 | Dust extraction port diameter | mm | 100 |

| 12 | Machine Dimension( L x B x H ) | mm | 4430 x 1370 x 2000 |

| 13 | Approx.net weight | kg | 1650 |

Four Side Moulders

Models:

J-4423 | J-4423 U | J-4523 | J-4523 U | J-4623 | J-4623 U | J-4416 | J-4516 | J-4616

A Machine that can give width, thickness & shape in one pass thus enhancing productivity and making it cost effective

Feed rolers are driven through gearboxes with power tranmission by shaft to give smooth feed of components. Fully adjustable spring loaded pad pressure assembly has been designed to ensure good stable control of the workpiece for improved quality finish. 360° Profiling to universal spindle. Adopting electric adjustment to rise and fall for easy to control.

Features :

* For making wooden floor, door frames, photo frames, wooden linings etc.

* Available in different configurations i.e. 4/5/6/7 depending upon application.

* Separate motor for each spindle to ensure efficient power transmission.

* All main spindle adjustments are done from outside the enclosure.

* Digital read out of spindle positions.

* Adjustable feed speed.

* Hard chrome plated work table for durability.

* Bottom driven bed rollers for increased feeding performance.

* Pneumatically operated top feed rollers for better feeding of stock.

* Safety enclosure to reduce noise level and operator safety.

* Centralized control & display system with adequate safety.

| Unit | J-4423 | J-4423U | J-4523 | J-4523U | J-4623 | J-4623U | |

|---|---|---|---|---|---|---|---|

| Capacity | 4 spindle |

4+1 spindle |

5 spindle |

5+1 spindle |

6 spindle |

6+1 spindle |

|

| Working width | mm | 20 - 230 | 20 - 230 | 20 - 230 | 20 - 230 | 20 - 230 | 20 - 230 |

| Working thickness | mm | 8 - 160 | 8 - 160 | 8 - 160 | 8 - 160 | 8 - 160 | 8 - 160 |

| Minimum working length | mm | 180 | 180 | 180 | 180 | 180 | 180 |

| Infeed table length | mm | 2000 | 2000 | 2000 | 2000 | 2350 | 2350 |

| Infeed table & fence adjustment |

mm | 10 | 10 | 10 | 10 | 10 | 10 |

| Feed speed with inverter | m/min. | 6 - 30 | 6 - 30 | 6 - 30 | 6 - 30 | 6 - 30 | 6 - 30 |

| Motor | |||||||

| First bottom spindle | hp | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| Right spindle | hp | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| Left spindle | hp | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| First top spindle | hp | 10 | 10 | 10 | 10 | 10 | 10 |

| Second top spindle | hp | N.A. | N.A. | N.A. | N.A. | 7.5 | 7.5 |

| Second bottom spindle | hp | N.A. | N.A. | 10 | 10 | 10 | 10 |

| Universal spindle | hp | N.A. | 10 | N.A. | 10 | N.A. | 10 |

| Feed drive motor | hp | 4 | 4 | 4 | 5.5 | 5.5 | 7.5 |

| Elevation motor power of universal spindle | hp | N.A. | 0.25 | N.A. | 0.25 | N.A. | 0.25 |

| Feed beam rise & fall | hp | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Total Power | hp | 38 | 48.25 | 48 | 59.75 | 57 | 69.25 |

| Cutting circles | |||||||

| First bottom spindle | mm | 108 - 145 | 108 - 145 |

108 - 145 | 108 - 145 |

108 - 145 | 108 - 145 |

| Right spindle | mm | 108 - 200 |

108 - 200 |

108 - 200 |

108 - 200 |

108 - 200 |

108 - 200 |

| Left spindle | mm | 108 - 200 |

108 - 200 |

108 - 200 |

108 - 200 |

108 - 200 |

108 - 200 |

| First top spindle | mm | 108 - 200 |

108 - 200 |

108 - 200 |

108 - 200 |

108 - 200 |

108 - 200 |

| Second top spindle | mm | N.A. | N.A. | N.A. | N.A. | 108 - 200 |

108 - 200 |

| Second bottom spindle | mm | N.A. | N.A. | 108 - 200 |

108 - 200 |

108 - 200 |

108 - 200 |

| Universal cutter | mm | N.A. | 108 - 180 |

N.A. | 108 - 180 |

N.A. | 108 - 180 |

| Max.OD for installing saw | mm | N.A. | 350 (3500 r/min.) |

N.A. | 350 (3500 r/min.) |

N.A. | 350 (3500 r/min.) |

| Max. length for installing cutter block |

mm | N.A. | 240 | N.A. | 240 | N.A. | 240 |

| Spindles | |||||||

| Axial adjustment to vertical spindle | mm | 30 | 30 | 30 | 30 | 30 | 30 |

| Axial adjustment to horizontal spindle (except 1st bottom spindle) | mm | 20 | 20 | 20 | 20 | 20 | 20 |

| Spindle diameter | mm | 40 | 40 | 40 | 40 | 40 | 40 |

| Rotation angle for universal spindle | degree | N.A. | 360º | N.A. | 360º | N.A. | 360º |

| Spindle speed | rpm | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 |

| Driven bed roller diameter between two top spindles | mm | 96 | 96 | 96 | 96 | 96 | 96 |

| Driven bed roller width between two top spindles |

mm | 253 | 253 | 253 | 253 | 253 | 253 |

| Other specifications | |||||||

| Max. air pressure on the infeed rollers |

bar | 6 | 6 | 6 | 6 | 6 | 6 |

| Dust extraction port diameter | mm | 150 | 150 | 150 | 150 | 150 | 150 |

| Machine dimension (LXBXH) | mm | 3560 x 1660 x 1700 |

3760x 1730 x 1750 |

3760x 1730 x 1750 |

4730x 1890 x 1750 |

4730x 1890 x 1750 |

5670 x 1890 x 1750 |

| Approx. net weight | kg. | 2700 | 3800 | 3800 | 4600 | 4600 | 5400 |

Glu Spreader

Models: Glu Spreader J-1300 GS

Main rollers has special lined rubber coating for proper grip and spreading of glue all along the width. Simple, effective and easy controls of the machine makes operator's work efficient.

Features :

* Can apply glue on single side or both sides of the panel.

* The thickness of gluing can be adjusted as required

* Adequate glue holding capacity between the rollers

* The rollers can be easily cleaned by cold or warm water

| Sr.# | Unit | J-1300 GS | |

|---|---|---|---|

| 1 | Max. gluing width | mm | 1300 |

| 2 | Max. gluing thickness | mm | 80 |

| 3 | Gluing speed | r/min | 33 |

| 4 | Installed power | kw | 2.2 |

| 5 | Machine dimension (LxBxH) | mm | 2350 x 900 x 1400 |

| 6 | Approx. net weight | kg. | 950 |

Highspeed Routers

Models: High Speed Router J-903 (Pneumatic) | J-902

Making volumes and profits at high speed !

Designed for high speed production routing for getting clean, fast cuts when routing, moulding, making dovetails, grooving, mortising, tenoning & rebatting. Pneumatic control up and down movement of spindles. Spindle drive assembly easily accessible for belt tension & maintenance. Engraving can be done on workpiece by copying the design of master jig.

Features :

* Balanced Spindles

* Pedal control spindle travel

* Brake System for spindle

* High speed bearings

* Large tiltable tables and throat clearance

* Rigid Construction with heavy base resulting in vibration free operation.

* Easily accessible controls

| Sr.# | Unit | J-903 (Pneumatic) | |

|---|---|---|---|

| 1 | Work table size | mm | 800 x 600 |

| 2 | Max. cutting thickness | mm | 60 |

| 3 | Lifting travel of work table | mm | 130 |

| 4 | Maximum table tilt | degree | 45º |

| 5 | Throat clearance | mm | 750 |

| 6 | Spindle rpm | r/min. | 8000/16000 |

| 7 | Guide pin diameter | mm | 6 & 12.7 |

| 8 | Shank diameter of cutter | mm | 12 |

| 9 | Spindle actuation | Pneumatic | |

| 10 | Compressed air requirement | hp/kg/cm2 | 1.5 / 7.0 |

| 11 | Installed power | kw | 2.4 / 3 |

| 12 | Machine dimension (L x B x H) | mm | 1500x800x1650 |

| 13 | Approx.net weight | kg | 560 |

Hot Press

Models: Hot Press J-100 T1 | J-100 T3

Quickest way to uniform thermal pressing, by design !

Application : Suitable for pressing & laminating on fibre boards, decorative papers, plywood & other lamination sheets. Can be used for Particle / MDF / HDF board.

Features :

* Rigid construction to take care of thermal distortion.

* Platens designed to have uniform temperature distribution system throughout its surface.

* Heavy duty hydraulic cylinders.

* Manual & semi-automatic controls.

* Parallel & smooth operation of platens.

* Pressure controller with indicator.

* Free floating cylinders to take care of alignment.

* Graphical & tabular pressure charts.

* With emergency stop controls.

| Sr.# | Unit | J-100 T1 (1-Layer) | J-100 T3 (3-Layer) | |

|---|---|---|---|---|

| 1 | Maximum load/pressure rating | ton/kg/cm² | 100 / 3.1 | 100 / 3.1 |

| 2 | Platen size | mm | 2500 x 1300 x 42 | 2500 x 1300 x 42 |

| 3 | Number of layers | nos. | One | Three |

| 4 | Qty.of pressing board | nos. | 2 | 4 |

| 5 | Opening between layers | mm | 300 | 100 |

| 6 | Number of hydraulic cylinder | nos. | 8 | 8 |

| 7 | Size of hydraulic cylinder | mm | 100 Ø | 100 Ø |

| 8 | Heating power | kw | 18 - 36 | 20 - 45 |

| 9 | Hydraulic pump power | kw | 5.5 | 5.5 |

| 10 | Hot oil delivery pump power | kw | 2.2 | 2.2 |

| 11 | Machine dimension (L x B x H) | mm | 3600 x 1650 x 2000 | 3600 x 1650 x 2150 |

| 12 | Approx.net weight | kg. | 6500 | 8500 |

Multi Boring

Models:

J-2700.in | J-21SH (Single Head) | J-21DH (Double Head) | J-21TH (Triple Head) | J-321 (Maggi)

Offering multiple application, flexibility and high-productivity

Cam System : This allows the setting of boring depth adjustments in horizontal & vertical positions for standard drills of following lenghts i.e. 57.5, 70, 77, 85.

Pneumatic clamps for clamping workpiece : Foot actuated 3 pneumatic clamps provided for adequate clamping of the work-piece. Prompt setting of clamps in vertical & horizontal axis. Maximum setting height of the clamps from the table is100 mm.

Alluminium head assembly : The alluminium head houses the mechanism of spindles & the center distance between each spindle is 32 mm. The spindles are cylindrical and have quick change chucks with enough clearance between the head & working table giving accessibility for tool change.

Control panel : A centralized control panel mounted in front cover for easy accessibility & operation. Pneumatic & electric compartment are separate for safety and easy accessibility for repair work, if required. Drill feed speed can be regulated from the control panel.

Adjustable side reference fence : Adjustable reference fences on the table allows setting of the panel for accurate dwelling. Two fences are provided for drilling small and big panels. A large extension fence can also be fitted on one side of the table. Each fence has flip-over stop for support.

| Unit | J-2700.in | J-21 SH | J-21 DH | J-21 TH | J-321 (Maggi) | |

|---|---|---|---|---|---|---|

| Working table size | mm | 1050 x 500 | N.A. | N.A. | N.A. | N.A. |

| Maximum working thickness | mm | 60 | 60 | 60 | 60 | 65 |

| Maximum Size of Work Piece (L x W) | mm | 1200 x 880 | 2400 x 640 | 2400 x 640 | 1800 x 640 | 3000 x 850 |

| Number of Spindle Head | no. | One | One | Two | Three | Three |

| Number of Spindle Head | nos. | 27 | 21 | 21 | 21 | 21 |

| Total Spindles | nos. | 27 | 21 | 21x2 = 42 | 21x3 = 63 | 21x3 = 63 |

| Center Distance Between Each Spindle | mm | 32 | 32 | 32 | 32 | 32 |

| Center Distance Between First & Last Spindle | mm | 832 | 640 | 640 | 640 | 640 |

| Minimum Center Distance Between 2 Vertical Heads | mm | N.A | N.A | 365 | 150 | 150 |

| Maximum Center Distance Between 2 Vertical Heads | mm | N.A | N.A | 445 | 1700 | 855 |

| Shank diameter of drill | mm | 10 | 10 | 10 | 10 | 10 |

| Spindle Rotation Speed | r/min. | 2800 | 2800 | 2800 | 2800 | 2800 |

| Maximum Drilling Diameter | mm | 32 | 32 | 32 | 32 | 32 |

| Drilling Depth | mm | 0~63 | 0~50 (drill length 70mm) |

0~50 (drill length 70mm) |

0~50 (drill length 70mm) |

0~50 (drill length 70mm) |

| Compressed Air Requirement | hp/kg/cm² | 1.5 / 5-7 | 1.5 / 6-8 | 1.5 / 6-8 | 2.00 / 6-8 | 2.00 / 6-8 |

| Electric Motor-3 Phase | hp | 3.00 | 2.00 | 2 nos. each of 2 HP | 3 nos. each of 2 HP | 3 nos. of each 2 HP |

| Machine Dimension (LxBxH) | mm | 1400 x 1130 x 1300 | 2500 x 1200 x 1200 | 2500 x 1200 x 1300 | 2700 x 2600 x 1500 | 1755 x 1033 x 1315 |

| Approx.Net Weight | kg. | 450 | 450 | 550 | 1050 | 800 |

Ocsillation Mortiser

Models:

Master Models:

A high grade PLC Mortiser with high performance & higher productivity!

The spindle head is manufactured from aluminum alloy & equipped with steel bearing bushing to avoid bearing loosening which may affect machining accuracy. Steel round rods on spindle slide ways. A mechanical meter provided on the mortise width adjustment mechanism ensures high accuracy adjustment Nitrogen cylinder support top cover firmly.

The machine is equipped with a PLC control combined with easy-to-read control panel, providing maximum operational convenience. The right and left mortising mechanisms are individually controlled on the control panel. Cutter oscillation frequency range is displayed on the control panel.

The machine is equipped with two tables at the right and left side allowing two operators to use simultaneously. Table tilts 35° at the right and left side. Table is elevated by turning a handwheel.

Features :

* Two table built in the front and back of the machine provides high efficiency mortising operations.

* Pneumatic clamps provided for convenient work piece clamping

* Mortising width and depth are adjustable

* Mortising tool oscillating speed is variable

* Mortising depth is accurately controlled

* Table height is adjustable

* Mortising bit oscillating speed is variable

| Sr.# | Unit | J-940 (auto) | |

|---|---|---|---|

| 1 | Max. mortise width | mm | 130 |

| 2 | Max. mortise depth | mm | 50 |

| 3 | Max.thickness of work piece | mm | 100 |

| 4 | Table size (LxB) | mm | 420 x 320 |

| 5 | Tilting of table | degree | 0º - 35º |

| 6 | Table stroke | mm | 60 |

| 7 | Table vertical adjustment | mm | 75 |

| 8 | Spindle speed | rpm | 9000 |

| 9 | Oscillation stroke | strokes /min | 0 - 340 |

| 10 | Spindle motor | hp | 2 |

| 11 | Oscillation motor | hp | 0.5 |

| 12 | Working air pressure | kg/cm2 | 5 |

| 13 | Machine dimension (LxBxH) | mm | 1360 x 1000 x 1410 |

| 14 | Approx. net weight | kg. | 470 |

Panel Saw

Models:

J-3200.in plus (manual) | J-3200.in (manual) | J-3200 MB (manual) | J-1600 MB (manual)

Pneumatic Clamp (Accessory for panel saw) | Also available SCM Panel Saws

Precision engineering, enhanced productivity functional ergonomics & sensible economics!

Now you have an option that's equivalent to Euro-quality precision machines, with a 'Pride of India' stamp. Panel saws of maximum strength & rigidity with value added features, with our assurance of quality, services and spares.

Precision sliding table with linear bearing developed with advanced technology with multi-chamber system for maximum rigidity of the double roller carriage. Anodized alluminum rip fence with sliding system on heavy round bar for parallel cutting up to 1250mm. Fine setting mechanism allows for precise measurements for parallel cuts. Easy & fast, saw-scoring blades changing. Also entire saw unit on heavy duty cast-iron trunnion.

Scoring saw precision lever mechanism for manual adjustment controls of the scoring saw with memory reference stop. The Sturdy frame prov ides a rigid support for all cutting with telescopic cross-cut fence with alluminum guides for precise and easy positioned. Also panels to be squared and cuts at an angle up to 45° on both sides of the table. Saw unit vertical movement on precise round guides ensures smooth operation. Its closed structure guarantees high rigidity & a vibration free unit.

| Unit | J-3200.in Plus | J-3200.in | J-3200 MB | J-1600 MB | |

|---|---|---|---|---|---|

| Sliding Table | |||||

| Sliding Table Length | mm | 3200 | 3200 | 3200 | 1600 |

| Sliding Table Width | mm | 415 | 360 | 360 | 316 |

| Main Saw Unit | |||||

| Max. Diameter Saw Blade | mm | 355 x 30 | 355 x 30 | 355 x 30 | 305 x 30 |

| Saw Blade Speed | rpm | 3000 / 4000 / 5000 | 3000 / 4000 / 5000 | 4000 | 4000 |

| Tilting of Saw Blade | degree | 90º - 45º (Manual) with digital read out | 90º - 45º (Manual) with digital read out | 90 º- 45º Manual | 90 º- 45º Manual |

| Max. Cutting Depth at 90º | mm | 105 | 105 | 105 | 70 |

| Max. Cutting Depth at 45º | mm | 75 | 75 | 74 | 50 |

| Up-Down movement of saw blade | Manual | Manual | Manual | Manual | |

| Motor For Saw Blade | hp | 7.5 | 5 | 5 | 5(common for saw & scoring unit) |

| Scoring Saw Unit | |||||

| Max. Diameter Scoring Blade | mm | 120 x 20 | 120 x 20 | 120 x 20 | 120 x 20 |

| Scoring Blade Speed | 8500 | 8500 | 8000 | 8000 | |

| Tilting of Scoring Blade | degree | 90º - 45º (Manual) with digital read out | 90º - 45º (Manual) with digital read out | 90º - 45º Manual | 90 º- 45º Manual |

| Up-Down movement of scoring blade | Manual | Manual | Manual | Manual | |

| Lateral Adjustment Scoring Blade | mm | ±3 | ±3 | ±3 | ±3 |

| Max. Depth of Cut off Scoring Blade | mm | 5 | 5 | 5 | 3 |

| Motor For Scoring Unit | hp | 1 | 1 | 1 | --- |

| Other Specification | |||||

| Cutting Width / Rip Capacity | mm | 1250 | 1250 | 1235 | 835 |

| Dimension Main Saw Table | mm | 610 x 1000 | 610 x 1000 | 610 x 1000 | 830 x 400 |

| Dimension Extension Table | mm | 800 x 1000 | 800 x 1000 | 800 x 1000 | 830 x 600 |

| Dimension Cross Cut Table | mm | 1500 x 600 | 1500 x 600 | 1270 x 650 | 620 x 500 |

| Length Cross-Cut Fence | mm | 2000 (telescopes to 3200mm) | 2000 (telescopes to 3200mm) | 1860 (telescopes to 3300 mm) | 1380 (telescopes to 2300mm) |

| Dust extraction port diameter | mm | 100 & 50 | 100 & 50 | 120 & 60 | 100 &60 |

| Machine Dimension ( L x B x H) |

mm | 3400 x 3770 x 1300 | 3400 x 3710 x 1300 | 3350 x 3910 x 1300 | 2200 x 2700 x 1300 |

| Approx. Net Weight | kg. | 800 | 750 | 650 | 275 |

Postform

Models: Postform J-2400.in (auto)

Automatic, speedier & easier yet excellent and error-free laminating of the profiled panels

Spl. Pneumatic guage : Operated by 2 cylinders for repetitive jobs setting.

Pressure Clamp : Having rubber pad, for better grip on workpiece to avoid damage.

PLC based control panel as standard feature : With a capacity of 20 progammes.

Features :

* 8 pneumatic cyclinders to apply uniform pressure on workpiece through forming rail for effective bonding of laminate.

* Ground and hard chrome plated heater bar for smooth operation and long life.

* Backstops facility provided to support long and odd shape jobs.

* Possibillity to laminate more than one small board at a time.

* Facilities for dry runs and manual runs provided for settings and trials.

* Automatic post-forming cycle with variable heating time, stop and go time & holding time, can be adjusted to profile.

* Driver motor with brakes is provided to avoid slippage of rotary motion of the heater frame.

* Mechanical drive control by limit switch.

| Sr.# | Unit | J-2400.in (auto) | |

|---|---|---|---|

| 1 | Maximum length of work piece | mm/feet | 2440/8 |

| 2 | Minimum length of work piece | mm | 600 |

| 3 | Workpiece thickness range | mm | 16-105 |

| 4 | Minimum work piece width | mm | 200 |

| 5 | Maximum heating temperature | ºC | 200 |

| 6 | Compressed air requirement | hp/kg-cm² | 2.0 / 7 |

| 7 | Heating element | kw | 3 |

| 8 | Electric motor - 3 phase | hp | 0.5 |

| 9 | Machine dimensions (L x B x H) | mm | 3300x1460x1830 |

| 10 | Approx.net weight | kg | 1300 |

Spindle Molder

Models: Spindle Moulder J-3400.in

Shape-up to the trends, mould your vision and upgrade to high-quality moulder

1300mm Sliding table for easy functioning. The hard anodized 1300mm alluminum extrusion sliding table is precision machined & features a 315mm wide table.

Clamping for tenoning A mitre fence with heavy duty wood clamp for tenoning and an alluminium extruded adjustable side reference fence.

Routing facility Spindle can be replaced with collet for routing work.

Features :

* A side reference of extruded alluminum which is adjustable.

* Clamping for tenoning work.

* Ground & electronically balanced spindle for vibration free operation.

* Easy and convenient system for locking of spindle shaft.

* Spindle driven by motors through V - belts and are housed in sealed bearings, thus ensuring minimum maintenance.

* 3 - spindle speeds 5000 / 7000 / 9000 RPM for selection depending on tool diameter.

* Dust chute is provided on fence assembly for dust evacuation.

| Sr.# | Unit | J-3400.in | |

|---|---|---|---|

| 1 | Fix table size | mm | 865 x 548 |

| 2 | Sliding table length | mm | 1300 |

| 3 | Sliding table width | mm | 315 |

| 4 | Spindle diameter | mm | 30 |

| 5 | Up / Down movement of spindle | mm | 100 |

| 6 | Arbour tilt | degree | 45º |

| 7 | Spindle speed | rpm | 5000 / 7000 / 9000 |

| 8 | Max. moulding block width | mm | 100 |

| 9 | Dust extraction port diameter | mm | 100 |

| 10 | Electric motor-3 phase | hp | 3 |

| 11 | Machine dimensions (LxBxH) | mm | 1550 x 1200 x 1200 |

| 12 | Approx.net weight | kg | 400 |

Tenoners

Models:

Round End Tenoner J-941 (auto) | Dovetail Tenoner J-8 M (manual) | J-16 M (manual)

Quickly process male and female tenons simultaneously!

Various tenon axis angles : It can be changed at horizontal, vertical and 45° by turning the positioning disk. A mechanical meter is provided for accuracy and adjustment of tenon sizes. The double table design enhances the productivity @ 12 pieces per minute.

Features :

* Tenoning width & depth is adjustable within specified limits.

* 2 speed to control for forward and backward speed.

* Variable speed suitable for cutting softwood & hardwood.

* The machine is furnished with solid Tungsten Carbide Tipped cutter.

* Pneumatic operated table for longitudinal travel.

* The movable table saves time.

* Tilting table with a miter gauge for cutting bevel tenons.

* The tenoning axis can be horizontal, vertical or 45° by changing the positioning disc.

* Digital mechanical meters is provided for adjustment of tenoning size.

| Unit | J-941 (auto) | J-8 M (manual) | J-16 M (manual) | |

|---|---|---|---|---|

| Max. tenon width | mm | 115 + 2R | ||

| Tenon depth | mm | 10 - 45 | ||

| Table tilt -Upward | degree | 0º - 15º | ||

| Table tilt -Downward | degree | 0º - 30º | ||

| Table tilt -Side | degree | 0º - 20º | ||

| Spindle speed | rpm | 6000 | 6500 | 6500 |

| Spindle motor | hp | 5 | 2 | 2 |

| Cutter cycle motor | hp | 1 | ||

| Production rate | pcs./min | 12 | ||

| Machine dimension (LxBxH) | mm | 1660 x 1150 x 1380 | 860 x 710 x 1270 | 1066 x 710 x 1270 |

| Approx. net weight | kg | 1100 | 350 | 450 |

| Number of tools | mm | 8 | 16 | |

| Work piece thickness | mm | 10 - 25 | 10 - 25 | |

| Max. work piece width | mm | 205 | 410 |

Trimmers

Models: Edge Trimmer J-3003.in (manual) | Profile Trimmer J-3004 (manual)

The master-stroke of finishing the edging of the laminates, made easy & productive

This unique machine is a complement machine to an Edge Bander, and it is designed to trim and buff both upper and lower edges on straight panels and then pneumatically cut to give a sized and smooth banding on the edges of the straight panel. The machine is also suitable for radius trimming when equipped with radius tools. The versatile nature of the machine allows differential trimming and/or buffing to be carried out either on top or bottom face of the panel or on the both panel faces.

Additional work table for end-cutting of edges with hylum surface, makes an operator's functioning easy. The spindle mechanism along with the trimming cutters and buffing wheels are housed in an elegantly designed cover having a transparent front end.

The control panel has various options and is user-friendly to operate the machine depending on the customer's requirement. In case the buffing is not required or only the top edge has to be trimmed and buffed, the various control buttons on the panel can be used for the operating options. A pneumatic cutter for cutting excessive band length after trimming & buffing

The trimming spindles can be adjusted in height (vertically) whereas the buffing spindle can be adjusted in height as well as laterally. This ability to adjust the spindles in vertical direction enables the setting of the cutters and buffing wheel with respect to the working thickness of the work piece. The horizontal adjustment is provided on the spindle of buffing wheel, which helps in adjusting the cutting plane of buffing wheel, so that the buffing wheel can be adjusted to give maximum operating life. This setting ensures the trimming and buffing of top and bottom edge of banding strip in one pass on straight panels.

| Unit | J-3003.in (manual) | |

|---|---|---|

| Main Table Size ( L x B) | mm | 1200 x 730 |

| Trimming Unit | ||

| Work piece thickness range | mm | 10 - 38 |

| Maximum trimming thickness | mm | 3 |

| Maximum Diameter of Cutter | mm | 75 |

| Spindle Speed | rpm | 12,000 |

| Lateral movement of upper cutter | mm | 3 |

| Total Power | hp | 0.33 x 2 |

| Buffing Unit | ||

| Work piece Thickness Range | mm | 10 - 38 |

| Maximum Diameter of buffing wheel | mm | 200 |

| Maximum width of buffing wheel | mm | 25 |

| Lateral movement of spindle | mm |

20 |

| Spindle Speed | rpm | 1400 |

| Total Power | hp | 0.5 x 2 |

| End Cutting Unit | ||

| Table Size | mm | 500 x 550 |

| Maximum cutting thickness | mm | 3 |

| Maximum width of work piece | mm | 10 - 70 |

| Compressed air requirement | hp/kg/cm2 | 0.5 / 7.0 |

| Other Specifications | ||

| Diameter of dust extraction port | mm | 100 |

| Machine dimensions (L x B x H) | mm | 1670 x 800 x 1350 |

| Approx. net weight | kg. | 350 |

Vacuum Mambrane Press

Models:

Vacuum Membrane Press J-1100 | J-1102

Vacuum-Lamination the mark of quality on panel-jobs, at high-production rate

Beautifying the laminated panel!!

Used for applying a uniform lamination of PVC, Decorative papers and Veneer till 0 .4mm on top surface & borders on flat & designed work piece having smooth shape. Centralized control panel for controls and display.

Features :

* Vacuum abnormity wrapping technology.

* Various models available having single table or double table construction.

* Lamination on one side of MDF & Solid Wood.

* Silicon membrane offered for veneer application.

* Short pressing cycles.

| Unit | J - 1100 | J - 1102 | |

|---|---|---|---|

| No. of working tables | nos. | 1 | 2 |

| Work table size ( L x B) | mm | 2300 x 1100 | 2300 x 1100 |

| Maximum height of work piece | mm | 50 | 50 |

| Total power | kw | 10 | 10 |

| Vacuum | mpa | -0.1 | -0.1 |

| Approx. overall machine dimension (L x B x H) |

mm | 5500 x 1450 x 1400 | 7600 x 1450 x 1400 |

| Approx.net weight | kg. | 1500 | 2000 |