| Previous Page | Glass Blowing Menu | Main Menu | Next Page |

|---|

The score and snap method of cutting glass tubes is fine for long lengths of small diameter tube, but for short lengths it is completely impractical. An outside diameter of 12mm is about the limit for this technique and the length of tube either side of the scratch has to be at least 100mm. It is also not safe to cut parts that have already been assembled.

A more versatile and reliable method is to score the tube all the way around and then use a hot wire on the scratch.

Above is a picture of my homemade hot wire glass cutter. The main box contains a 1A variable auto-transformer and a step-down transformer from an old Superspeed soldering iron. The maximum output from the soldering iron transformer is 3.5V rms at 150VA. The knob on the right controls the auto-transformer and is used to adjust the power dissipated in the nichrome wire.

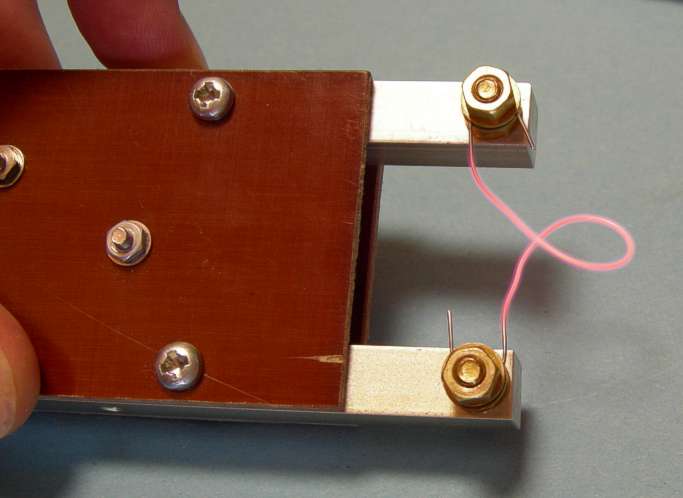

The hand held part is made from aluminium bar and Tufnol sheet. There is also a microswitch inside operated by a button on the side. This applies power to the nichrome wire, heating it up. The nichrome wire loop is bolted to the ends of the bars. The wire diameter is 0.5mm. Different shaped wire loops can be attached for different tube diameters. One of the bars is connected to earth for electrical safety.

A schematic diagram is shown above. This can be clicked on for a higher resolution image. Fuses FS1 and FS2 are on the rear of the main unit. S1 is the main power switch, which is on the left had side of the front panel. T1 is the auto-transformer, used to adjust the power level. S2 is the microswitch in the handle, and T2 is the Superspeed soldering iron transformer.

The inside of the unit is not exactly a work of art, but it's functional and reasonably safe.

Above, a 12mm diameter tube is being scored using a Philip Harris glasswork knife. The operation is assisted by the use of an Emco Unimat 3 metalwork lathe. The lathe was set to minimum speed.

The glowing wire is shown above. It is actually more of a red colour, but the infra-red causes colour distortion in the camera. Different size loops can be fitted for different sizes of tube.

The score is moistened and then the hot wire is applied to the scratch. The tube is slowly rotated in the wire loop to propagate the crack all the way around.

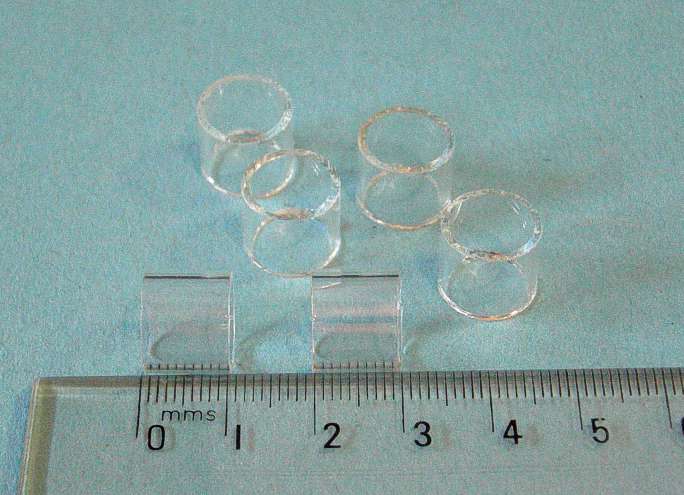

A set of 10mm length pieces accurately cut using the above method.

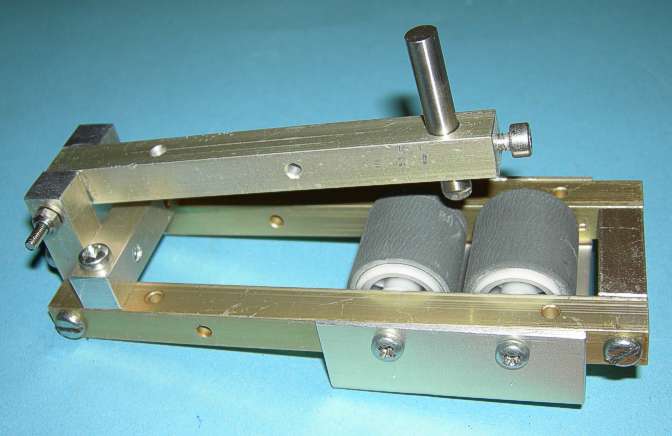

Glass tubing often comes in 1.5m lengths. This is too long to fit in my small lathe. I made the tool shown above from 10mm x 10mm aluminium bar. The rollers were from an old laser printer. They are ideal because they grip the glass tubing but do not deform excessively. They also have integral bearings.

The blade can move up and down via the arm, but not from side to side. The arm is mounted on a shaft, but I found I had to drill a hole through and fit a screw and nylock nut to pull the two upright pillars together and prevent slack developing which would allow the arm to wobble. The rollers also have PTFE shims fitted either side of them so that they can not move from side to side. There must not be any slack or it would cut a spiral. It has to be accurate enough that it can score all the way around a tube and the ends of the score meet up exactly.

| Previous Page | Glass Blowing Menu | Main Menu | Next Page |

|---|