| Previous Page | Glass Blowing Menu | Main Menu | Next Page |

|---|

A straight length of 8mm diameter tube would suffice for this glow tube, but I decided to use one of the 'U' tubes from the Bending Tubes page.

One end of the tube has to be sealed off. I used the same method for this as the preparatory

stage of Blowing

Bulbs.

One end of the tube has to be sealed off. I used the same method for this as the preparatory

stage of Blowing

Bulbs.

It would have been a little easier to seal the end of the tube before bending it.

For the glass to metal seals, I used pins recovered from an old TV valve. I have found

that they can be sealed in more easily if they are pre-beaded with glass. This can be

done with a glass rod which has been drawn out thin. I hold the pin with a pair of pliers

and heat the glass and the pin at the same time. I wrap one end of the thin rod around the

necked part of the pin and then draw the rod away so that it detaches. I turn the gas

up high and rotate the pin in the flame until the glass melts into a round bead.

For the glass to metal seals, I used pins recovered from an old TV valve. I have found

that they can be sealed in more easily if they are pre-beaded with glass. This can be

done with a glass rod which has been drawn out thin. I hold the pin with a pair of pliers

and heat the glass and the pin at the same time. I wrap one end of the thin rod around the

necked part of the pin and then draw the rod away so that it detaches. I turn the gas

up high and rotate the pin in the flame until the glass melts into a round bead.

These are the pre-beaded valve pins. The part to the right of the glass bead is the pin

which plugged into the valve socket. The part to the left of the bead was originally

inside the valve. I have cut it short so that it will fit inside the 8mm diameter tube.

These are the pre-beaded valve pins. The part to the right of the glass bead is the pin

which plugged into the valve socket. The part to the left of the bead was originally

inside the valve. I have cut it short so that it will fit inside the 8mm diameter tube.

The necked part of these pins is

Dumet

, which produces a bubble free seal.

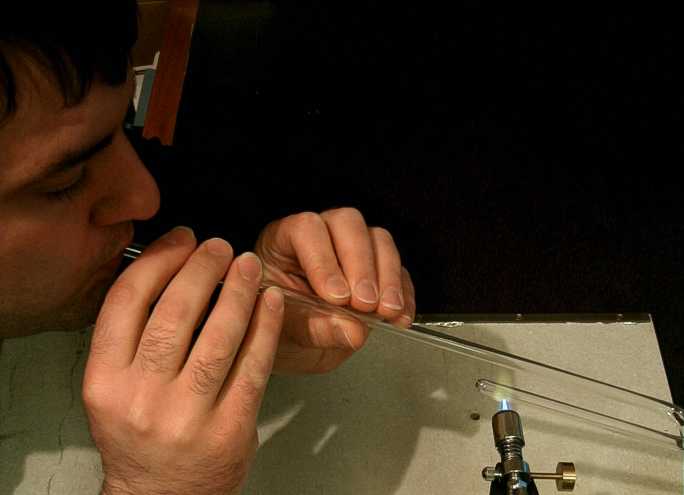

The seals have to be fitted one at a time. A small area near the end of the tube needs to be blown out in order to fit a glass to metal seal pin. This requires a very sharp flame. This is one of the few times where I blow into the tube while it is in the flame. A picture of this is shown below. The aim is to blow out an area just big enough for the wire to go through, but too small for the bead. I find that to get the glass to extend outwards, it is necessary to blow very gently.

This is the end of the tube after the side has been blown out. It is a bit wonky but

adequate for a good seal.

This is the end of the tube after the side has been blown out. It is a bit wonky but

adequate for a good seal.

To seal in the pin, the pin and the blown out side of the tube have to be heated

at the same time. I used the bunsen type burner for this. I then simply pushed the

softened bead into the hole in the tube. I then annealed it and allowed it to cool

slowly.

This is one of the completed seals. The glass bead has fused into the surrounding glass

of the tube.

This is one of the completed seals. The glass bead has fused into the surrounding glass

of the tube.

The other pin now has to be sealed into the other arm of the 'U' tube. This is done in the

same way as the first pin.

Here the tube is mounted on top of the vacuum rig. The tube contains air at 10mBar.

A very high voltage is required to strike the discharge. Here I was using about

8kVac.

Here the tube is mounted on top of the vacuum rig. The tube contains air at 10mBar.

A very high voltage is required to strike the discharge. Here I was using about

8kVac.

The tube could be sealed off at this point, but I decided to wait until I have some way of

filling it with neon gas. This would give much better results.

| Previous Page | Glass Blowing Menu | Main Menu | Next Page |

|---|